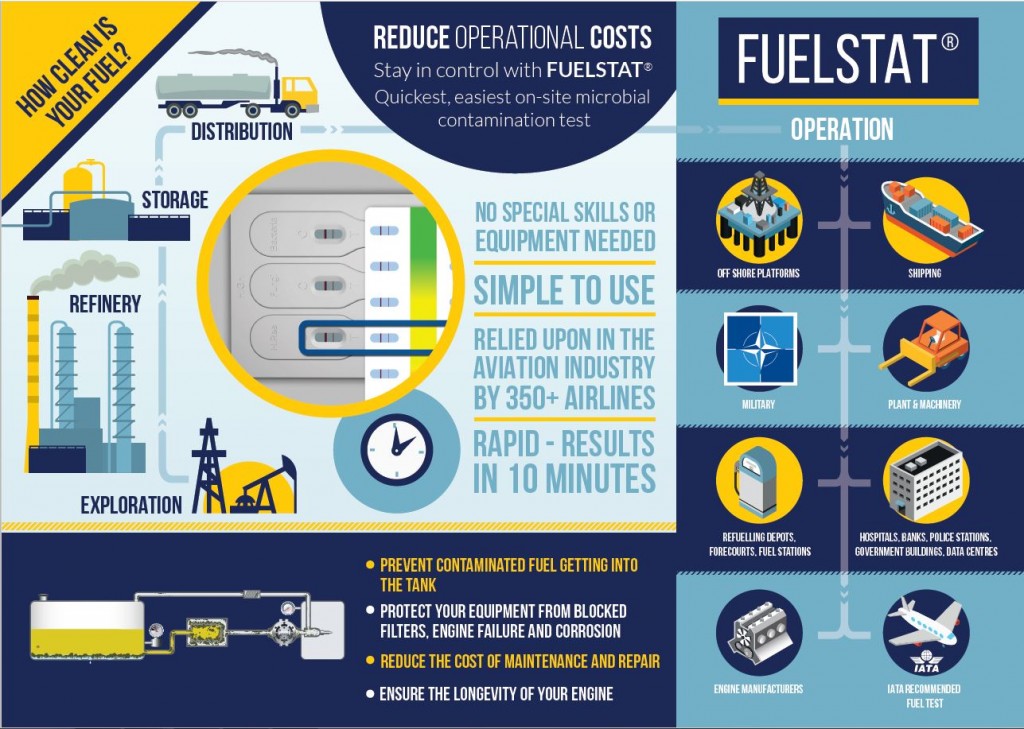

Purpora Engineering has partnered with Conidia Bioscience to offer a simple to use, quick response test kit for microbial contamination in Diesel fuel.

Why test your fuel for microbial contamination?

- Prevent contaminated fuel from getting into the fuel tank

- Protect your equipment from blocked filters, engine failure, and corrosion

- Reduce the costs of maintenance and repair

- Ensure the longevity of your engine

Why use FUELSTAT®?

- Relied upon in the aviation industry by 400+ airlines

- Quicker and more accurate than other tests on the market

- Easy to use, transport and dispose of

Applications in use

Offshore Platforms-Back-up power generators and Diesel powered life crafts. Commonly operators take a sample which is then sent back to shore for analysis. By the time the results are returned the environment will have changed and, therefore, any prescriptive measures may no longer be appropriate. This is, potentially, a waste of time and money. Failure of a gas recovery unit due to a drop in pressure and subsequent failure of the diesel powered back-up power generation unit is a huge cost to the operator and could run into thousands per day in downtime.

Shipping-KEEP the vessel MOVING If a ship is in port with a suspected fuel contamination problem the cost of extended moorage, penalties for late delivery and lost sailing days could be very expensive for the carrier. More critically, if the ship were to breakdown, the cost of towage and repair would be extremely expensive. The impact is increased further by the introduction of the new ECA regulations concerning the use of Heavy Fuel Oil in certain coastal areas, which means operators will now have to run Marine Gas Oil in those zones. As the Gas Oil will sit, unused, in fuel tanks while the ship is in open water, there is a great chance of contamination occurring.

Military FUELSTAT® carries a NATO Stock Number and is used by a number of branches around the globe. The test is most useful on deployments away from fixed bases, when the normal maintenance regimes cannot be relied upon.

Fuel Stations-If there is a potential fuel contamination issue, these sites cannot remain out of service for long. The ability to conduct a simple, on-site test is therefore critical to the ongoing operation of the site.

Plant and Machinery-A lot of heavy plant and machinery is used on remote sites, often taking their fuel from a refueling site also in remote areas. The ability to conduct a test with rapid results and carry-out remedial action can be the difference in meeting project deadlines and ensuring the equipment is functioning properly.

Hospitals, Banks, Police Stations, Government Buildings, Data Centers-These buildings will usually have some sort of back-up power, often diesel powered, which will sit idle for long periods of time. The consequences of a malfunction when the generators are needed can be serious, even fatal.

Engine Manufacturers-Diesel engines have become more complicated in order to meet stricter environmental standards. However, little has changed within the fuel that powers them or the climatic effects which create microbial contamination. As a result there is an increase in cases of engines suffering from fuel system related warranty claims and frequent filter changes. The combination of these factors is costing manufacturers a substantial amount of money. A number of manufacturers are beginning to inform clients of potential fuel contamination and introduce measures in order to alleviate the problem by fuel testing at regular intervals.

For more information please watch the demonstration video and/or contact us at 262-536-4081. To order kits online: Fuel Stat Kits